The two-year conference at the SKZ-Modellfabrik Würzburg on 1 and 2 July 2025 offered a comprehensive insight into current developments and trends in barrier laminates. The focus was on new material solutions and innovative manufacturing processes for monomaterials. In addition, the performance of modern films was impressively demonstrated and precise measurement methods for permeation measurement were presented.

Dieter Finna · www.pack-consult.org · (For a German version click here).

All those working on the future of barrier laminate films found access to the latest developments at this conference. The event provided valuable input on current trends in film extrusion and sustainable packaging concepts with innovatively produced polyolefin films. The two-day event also offered a first-class exchange with experts from the packaging industry. Karsten Schröder moderated the programme. Here is a brief summary of the presentations.

In his presentation, Dr Thomas Gröner (TG Pack Solutions) demonstrated the effects of the Packaging & Packaging Waste Regulation PPWR on barrier packaging. Firstly, he addressed the responsibility of producers and manufacturers. The producer manufactures the packaging and is responsible for its conformity, while the manufacturer places packaged products on the market and is responsible to the authorities. Key challenges arise from the general requirement for packaging to be recyclable from 2030 and the fulfilment of minimum recyclate content requirements for plastic packaging. Multi-material laminates are particularly problematic as they often cannot be sorted or recycled. Manufacturers must therefore focus more on mono-material solutions, recycling-orientated design and improved separability.

In his presentation, Florian Reiter from Borealis showed how the properties of monoaxially oriented polyolefin films can be significantly improved through targeted material selection and process control. High oxygen barriers of up to < 0.5 cm³/(m²*bar*d) can be achieved with orientated films in the machine direction (MDO) and their sealing window can be extended to 130 – 170°C with reduced shrinkage in the sealing areas. Monoaxially oriented PE composite films achieve higher mechanical strength and thermal stability with improved process efficiency when processing the films. Such solutions, which are found in Design for Recycling (DfR), require co-operation along the entire process chain.

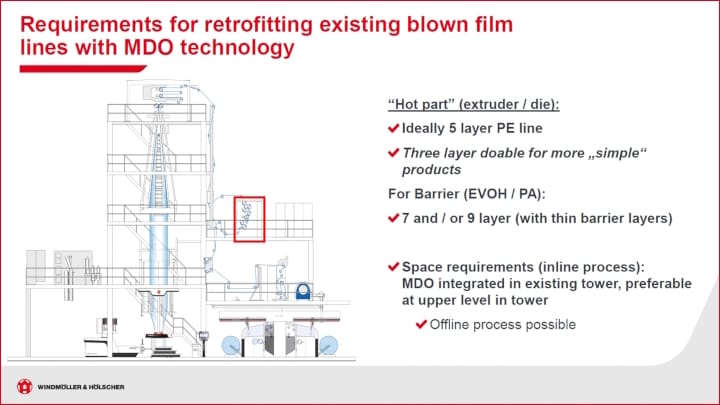

Examples of optimised packaging design by DfR. Source: Windmöller & Hölscher SE & Co. KG)As part of his presentation, Hendrik Steen (Windmöller & Hölscher) presented innovative concepts for retrofitting MDO units for more efficient barrier film production. 5-layer PE blown film lines are particularly suitable for such a retrofit. For less complex applications, the MDO process can also be applied to three-layer laminates. To produce high-quality EVOH/PA barrier films, however, the use of 7- or 9-layer systems is recommended. An essential prerequisite for the successful integration of an MDO unit is that both the design of the existing extruder and the die head as well as the spatial conditions in the plant tower enable efficient production. With the implementation of Optifil P-MDO automation, the edge trim of the films can be reduced by up to 50% – a major step towards significant material savings. Overall, the MDO retrofit also helps to increase production efficiency. The production of MDO PE films is a sustainable alternative to conventional PET/PE laminates and opens up new market opportunities and additional sales potential in this field.

The presentation by Dr Benedikt Hauer (Fraunhofer Institute for Physical Measurement Techniques IPM) dealt with the metrological requirements for the inline quality control of ultra-thin inorganic barrier layers (< 50 nm) on polymer substrates. These ultra-thin oxide layers are used to prevent oxygen diffusion through the packaging. The measuring principle for the necessary quality control is based on infrared reflection spectroscopy, in particular the analysis of characteristic Si-O and Al-O vibration bands. This was demonstrated using a practical example of inspection during production in an industrial batch coating system. In roll-to-roll systems, thin-film interference, strip flutter and vacuum conditions represent significant challenges for measurement. This is solved by compact, calibrated infrared sensors with short measurement times, high parallelisation capability and spectral filter technology for determining coating thickness in real time.

Norbert Runn (Polytype Converting) presented sustainable production targets with innovative technologies. The PGS pressurised doctor blade coating system, developed jointly with BASF, enables maximum precision in coating and significantly reduces material losses as well as return and investment costs. Together with Mitsui Chemical, multi-layer suitable barrier coating media were developed, which are particularly suitable for paper-based coatings, in addition to existing solutions for film-based packaging materials. With multi-layer curtain coating, several coating layers are applied in one position. Calendering technology is an energy-efficient and resource-saving process and can be used in a variety of ways, for example for the solvent-free lamination of packaging films and for cooling melted PET film.

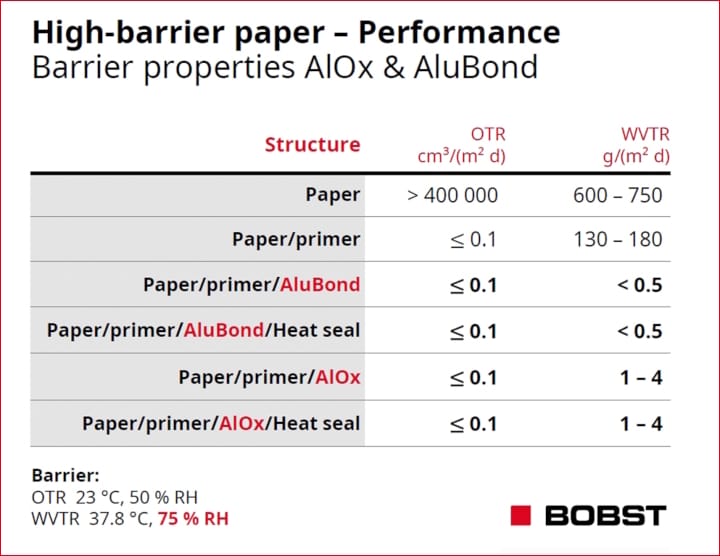

Marco Schmidt (Bobst Meerbusch) presented the oneBARRIER concept as a sustainable solution for flexible paper-based packaging with a high barrier effect. The combination of primer and barrier layers such as AlOX or AluBond (metallisation), supplemented by a heat-seal coating, creates an effective oxygen and water vapour barrier that can replace metallised polyester and even aluminium foil structures. It remains effective even after the packaging material has been folded, as the folding test proves. The barrier material is recyclable in accordance with CEPI, Aticelca and PTS standards and achieves up to 95 % recyclability. Examples of applications include packaging for food and household products that are both recyclable and functional.

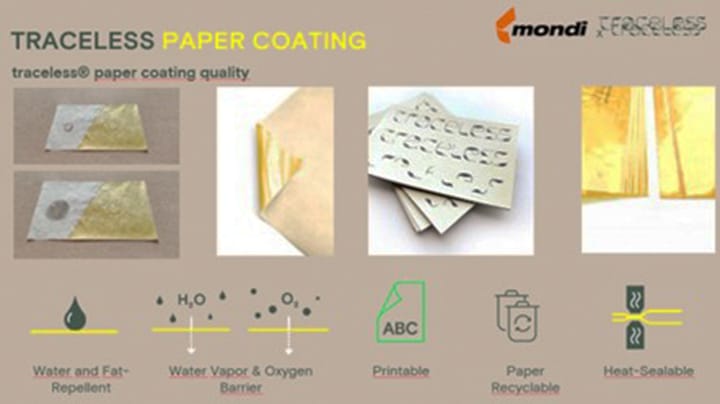

Properties of paper coated with traceless. (Source: traceless materials GmbH)In a joint presentation, Thomas Lunz (Mondi Functional Paper & Films) and Marissa Schwinn (Traceless Materials) showed which possibilities recyclable barrier papers already offer today and what can be expected in the future. Mondi has all the technologies, including extrusion and dispersion coatings as well as metallisation. The barrier papers fulfil both functional and high mechanical requirements and, depending on the regional system, can be recycled in the paper or light packaging stream. For example, unbreakable barrier alternatives to aluminium laminates can be realised.

traceless materials develops home-compostable, innovative biomaterials with a negative carbon footprint made from plant-based residues from the agricultural industry. The biopolymers used are considered plastic-free. In collaboration with Mondi, a paper coating is being developed that offers water vapour and oxygen barriers as well as heat sealability – without impairing the paper recycling process.

In his presentation »Less is more – sustainability, life cycle assessment and consumer behaviour«, Dr Phil Rosenow (Fraunhofer Institute for Process Engineering and Packaging IVV) emphasised that sustainability in packaging is not achieved by simply saving on materials. Underpackaging increases food losses, while overpackaging causes unnecessary environmental impacts. Food losses have a greater environmental impact than packaging. A function-driven life cycle analysis (LCA) takes into account the protective function, shelf life and consumer behaviour. Using the example of minced beef, he showed that optimised barrier design extends shelf life and reduces climate impact. Sustainable packaging balances material use and protective effect, which is currently being investigated at the institute in further case studies for crisps, yoghurt and fruit.

In his presentation »Using bacterial cultures as a natural oxygen absorber for sausage products packaged in mono-PET«, Andreas Dietrich (Weber Food Technology) pointed out that the oxygen in sausage packaging comes from the packaging process, the product and the inadequate barrier effect of mono-PET. The consequences are photo-oxidation, loss of colour under the influence of cold white LED light, loss of freshness and faster spoilage. Cultures such as Bactoferm Rubis act as natural oxygen absorbers. They bind O2 metabolically, stabilise colour, extend shelf life and enable »clean label« packaging without synthetic additives – a sustainable solution for modern, recycling-friendly packaging materials with a reduced barrier.

Dr Ferdinand Somorowsky (Fraunhofer ISC) presented a fibre-based stand-up pouch with a barrier function based on bioORMOCER hybrid polymers developed in the EU project InnPressMe. These are materials that combine ceramic barrier properties with polymer flexibility. Paper, PLA-X dispersions and bioORMOCER were processed using conventional methods. The bags consist of over 85% bio-based materials, are recyclable, biodegradable and achieve barrier values of OTR 2–4 cm3/(m2 d bar) and WVTR up to 6 g/(m2 d). Compared to conventional plastic bags, they offer significant ecological advantages with comparable functionality and suitability for food packaging.

In his presentation, Dr Philipp Okle (Amcor Flexibles Kreuzlingen AG) showed the advantages of SiOx barriers for PP/PE-based, high-barrier and sterilisable packaging. They are a sustainable alternative to AlOx and aluminium. SiOx offers better transparency, mechanical stability and recyclability. Compared to AlOx, SiOx barriers have a lower defect density of typical barrier defects and higher processing robustness. Applications range from baby food to pet food. Life cycle analyses (LCA) and recycling studies confirm that packaging with a SiOx barrier reduces the carbon footprint by up to 60 % compared to conventional PET/aluminium/PP solutions and therefore fulfils key requirements of the Packaging & Packaging Waste Regulation (PPWR).

Dr Ulrike Helmstedt (Leibnitz Institute for Surface Modification) explained how UV radiation opens up new ways of producing transparent, flexible barrier coatings. VUV conversion (vacuum ultraviolet radiation) can be used to produce ceramic oxide layers (e. g. SiOx, AlOx) at ambient temperature and normal pressure – without a vacuum process. In this way, sensitive substrates (e. g. PET) can be coated cost-effectively. This opens up prospects for sustainable, thermoformable and conductive barrier systems. Nanocomposite barriers produced with UV-initiated polymerisation use special fillers to extend the diffusion paths for gases (tortuosity principle). UV-curable resins also enable thicker, VOC-free protective coatings without hot air drying.

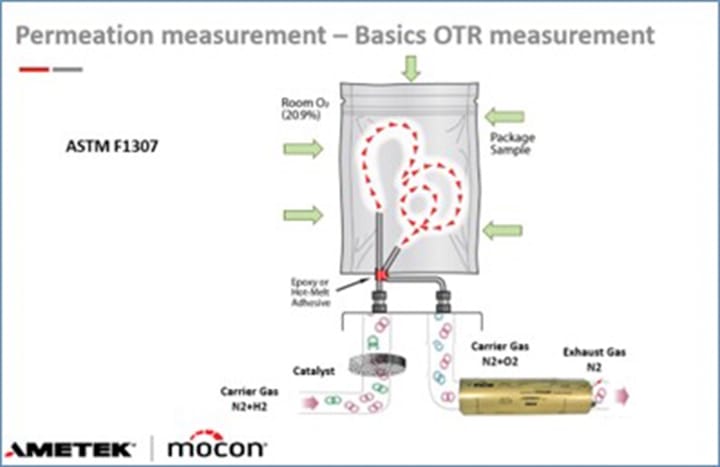

Schematic structure of a permeation measurement of flexible packaging. (Source: Ametek GmbH, Business Unit Mocon)Christoph Zerwas (Ametek, Business Unit Mocon) showed new approaches to barrier measurement for flexible packaging. They are becoming increasingly important, particularly in view of the growing variety of materials and increasing requirements for accuracy and reproducibility. The classic preparation of a permeation measurement with cutting and subsequent gluing with epoxy resin is time-consuming, error-prone and also critical to health. The new clamping solution using an adapter replaces gluing, saves up to 90% preparation time, halves the measurement scatter and increases measurement reliability. This makes measurement significantly more efficient and sustainable – while reducing waste and operating errors at the same time.

In his presentation »Leak testing as a supplement to permeation measurements«, Alexander Tovar (Inficon GmbH) pointed out that permeation can only be measured correctly if the packaging is completely sealed. However, the tightness of packaging is not an absolute condition, but is defined by verifiable leakage rates or O2 concentrations. The selection of suitable test methods is based on these specifications. There are numerous measurement methods – from sensory tests to high-precision differential pressure and gas measurement methods. The pressure rise test in a flexible film chamber is particularly impressive due to its non-destructive, fast and reproducible results. For 100% control in production, partially automated in-line systems are used to ensure high quality and process reliability.

Dr Kristina Eißenberger (Albstadt-Sigmaringen University of Applied Sciences) presented recyclable metallised multilayer films with an innovative protein barrier layer. Metallisation of the protein-based layer significantly improves the oxygen barrier, which increases product protection. At the same time, separable material structures enable single-origin recycling of the individual layers. The process allows enzymatic degradation of the protein coating, resulting in high-quality recyclates. These can be reused in closed material cycles. The aim is to create sustainable, bio-based packaging with a high level of functionality in the future, which enables a real circular economy through customised end-of-life solutions.

Summary

Karsten Schröder concluded the conference with a concise summaryof all the presentations. It is time to think about packaging independently of the material. Depending on the application for which a packaging material is better suited, this may be paper, but for another application it may be (laminated) film or possibly even biomaterial. It is important to use the most suitable material in each case and not to think ideologically in one direction. This is what the PPWR demands and the big slogan is „Minimise“! In its compactness, the conference showed that minimal packaging is not a trend, but the future. Innovation, dialogue and collaboration are driving sustainable solutions and shaping the packaging world of tomorrow.

[Bildlegenden:]

[01 SP-07-25 barrierefolien_innoform_event_header_v2.jpg]

(Source: Innoform Coaching GbR)

[02 Borealis Design for Recycling eng.jpg]

Examples of optimised packaging design by DfR. (Source: Borealis Polyolefine GmbH)

[03 Nachrüstung mit MDO Technology.jpg]

The design of the existing extruders must be suitable for retrofitting. (Source: Windmöller & Hölscher SE & Co. KG)

[04 Druckkammerrakel-Beschichtungssystem.jpg]

The PGS pressurised doctor blade coating system has extremely low coating tolerances. (Source: BASF SE)

[05 Hochbarriere auch auf Papier.jpg]

Oxygen and water vapour barrier of different barrier layers. (Source: Bobst Meerbusch GmbH)

[06 Eigenschaften des mit Traceless beschichteten Papiers.jpg]

Properties of paper coated with traceless. (Source: traceless materials GmbH)

[07 Farbstabilität und Frischeerhalt mit Bactoferm Rubis.jpg]

Colour stability and freshness retention with Bactoferm® Rubis. (Source: Weber Food Technology SE & Co. KG)

[08 Ormocer Sauerstoffbarriere.jpg]

Barrier properties of various Ormocer® formulations. (Source: Fraunhofer Institute for Silicate Research ISC)

[10 Permeationsmesssung Flexibler Verpackungen.jpg]

Schematic structure of a permeation measurement of flexible packaging. (Source: AMETEK GmbH, Business Unit Mocon)