How collaboration along the supply chain supports the implementation of PPWR

Masterpress SA, a manufacturer of labels and shrink sleeves in Białystok/PL is implementing the development of sustainable packaging solutions in close cooperation with the supplier industry. The company’s first »Media Day« highlighted specific ways of collaborating in the label supply chain that are fully in line with the requirements of the European Packaging Regulation (PPWR).

Dieter Finna · www.pack-consult.org · (Click here for a German version).

On 4–5 June 2025, Masterpress offered the European trade press the opportunity to learn about the company’s latest developments. The focus was on the label and packaging manufacturer’s path to sustainable packaging solutions, which Masterpress presented as part of its cross-industry collaboration. It benefits from complementary skills, the sharing of resources and mutual inspiration in terms of concepts and strategies. This creates added value that goes beyond purely additive cooperation.

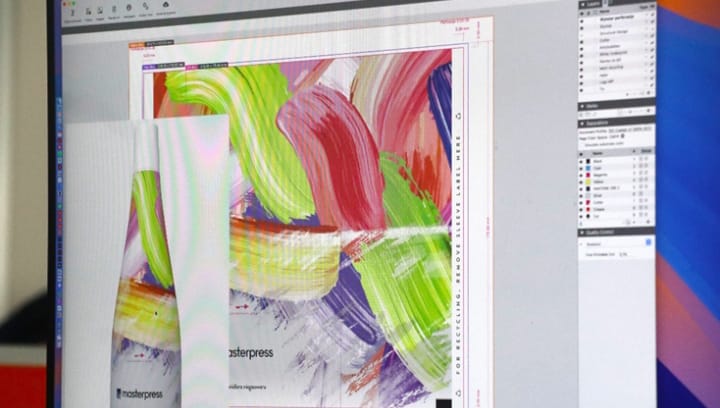

The company tour impressively demonstrated how label converters today must master the combination of printing and processing systems. In prepress, Masterpress relies on the Automation Engine workflow software, which, among other things, enables precise distortion for shrink sleeve applications on a wide variety of container shapes. It also implements print-specific adjustments such as trapping.

Investments in hybrid printing systems with 12 and 14 printing units reflect the company’s technological aspirations. These enable Masterpress to offer more environmentally friendly shrink sleeve printing solutions, for example through energy-efficient UV LED curing and the pioneering technology of printing on films with a thickness of 12 micrometres, which contributes to more efficient use of resources. Both of these trends were proactively addressed by Masterpress at an early stage.

Masterpress‘ investments also include a hybrid machine operated specifically for R&D, which combines UV flexo and gravure printing. It combines UV flexo with five gravure printing units and is used to test innovative effects in new designs as well as to develop recyclable label solutions. With its well-equipped R&D department, Masterpress can pick up on development trends and developments at an early stage and work with suppliers and institutes to turn them into marketable solutions. In addition to the PPWR, other important regulations such as the German Printing Ink Ordinance (GIO) are also taken into account. The R&D team is currently testing a film with a 50% recycled content. Together with Siegwerk, the first complete UV flexographic printing deinking system on the European market has also been developed. Internal laboratory tests at Masterpress and the ink manufacturer show high-quality recyclate quality.

Established in 1966, Masterpress SA is a leading European supplier of high-quality labels and innovative printed decorative packaging solutions. Headquartered in Białystok, Poland, the company employs approximately 350 people and offers complete solutions within the entire scope of the shrink sleeve industry: production of sleeve labels, self-adhesive labels, label application services, as well as production, installation and servicing of full sleeve application lines.

Innovation requires cooperation

The European Packaging Regulation not only poses regulatory challenges, but also offers an opportunity for the packaging industry, according to Masterpress and the industry representatives present. Admittedly, the legal framework of the regulation remains vague in these areas, with many details still to be defined. But this is precisely where the potential lies: the regulation not only forces a rethink, but also actively encourages cooperation across company and industry boundaries.

Panel Discussion

Removing the »buzz« in collaboration – delivering a »competitive« EU PPWR through collaborative efforts across the packaging supply chain.

During the panel discussion, industry representatives emphasized the central role of cooperation in implementing the EU Packaging Regulation. While packaging development has primarily focused on optimizing costs and performance to date, the integration of sustainability into the development process is now coming to the fore – an enormous challenge.

In addition to design and material use, it is also important to invest sufficient resources in the collection and sorting of packaging. Recycled materials, as presented in the laboratory during the company tour, are currently more expensive than new materials – a problem that must be solved urgently in order to achieve the goals of the PPWR.

Another point of discussion is whether consumers are willing to pay more for sustainable products. One opinion was that if the industry itself is not currently willing to bear higher costs, this cannot be demanded of consumers. As an industry, we must take responsibility ourselves and invest equally in this transformation. It is about securing the future viability of the industry so that we can continue to do business in the next 20 or 30 years.

True innovation can only come about through dialogue with partners along the entire supply chain – from material development to printing to recycling. The ambitious goals of the PPWR, such as reducing packaging, using recyclable materials and achieving binding recycled content quotas, can only be achieved through joint efforts. The engaging discussion made it clear that while many questions still need to be answered and rules defined, this very openness holds the potential to develop successful and forward-looking approaches together.