Insignis Etiketten focuses on versatility and an all-round printing system

Dieter Finna (Click here for a German version)

Vienna-based Insignis Etiketten GmbH uses the Gallus Labelfire with Digital Embellishment Unit (DEU) to respond flexibly to customers’ special requirements. The hybrid UV inkjet printing press combined with inline finishing has established itself as an all-round printing system due to the versatility of its production options. Insignis has optimised its production and expanded its product portfolio thanks to the expertise it has gained from using the Labelfire. Pack.consult spoke to Anna-Carin Speneder and Ferdinand Hager about the possibilities offered by this printing system with its digital finishing unit.

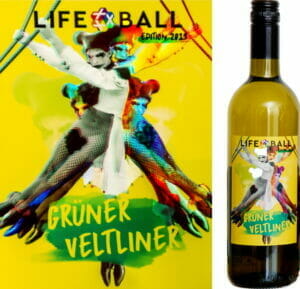

Insignis Etiketten supplies almost all market segments, especially food and beverages with a focus on wine and spirits, as well as pharmaceuticals and cosmetics. Industrial customers, including those from the automotive sector and the textile industry, as well as logistics and transport companies, also account for a significant share of their customer base.

Insignis’s wide range of machinery includes offset, letterpress and flexo as well as digital print solutions with dry toner and inkjet. UV inkjet with digital inline finishing plays a central role in economically implementing creative solutions in their printing of labels and flexible packaging.

Wide range of design options

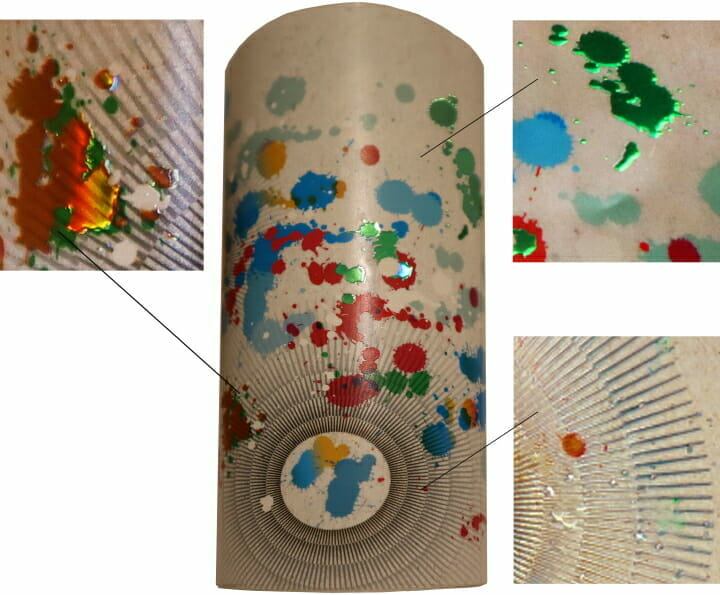

»From the design side, we have completely exhausted the technical possibilities of the Labelfire«, says Anna-Carin Speneder, Head of Sales Customer Service at Insignis GmbH, describing the use of the hybrid machine system. Capable of combining conventional UV inks in flexo printing, UV inkjet inks in digital printing, digital metallic doming with cold foil, matt as well as glossy spot varnishing, through to tactile relief special effects coatings, with an application possibility of up to 72 g/m2, the digital printing system offers almost inexhaustible design potential. Insignis uses these diverse design elements to offer all manner of unusual customer solutions. Inline coating with the Digital Embellishment Unit allows three different coating effects in a single pass, replacing up to three conventional printing stations in the production steps.

»From the design side, we have completely exhausted the technical possibilities of the Labelfire«, says Anna-Carin Speneder, Head of Sales Customer Service at Insignis GmbH, describing the use of the hybrid machine system. Capable of combining conventional UV inks in flexo printing, UV inkjet inks in digital printing, digital metallic doming with cold foil, matt as well as glossy spot varnishing, through to tactile relief special effects coatings, with an application possibility of up to 72 g/m2, the digital printing system offers almost inexhaustible design potential. Insignis uses these diverse design elements to offer all manner of unusual customer solutions. Inline coating with the Digital Embellishment Unit allows three different coating effects in a single pass, replacing up to three conventional printing stations in the production steps.

»What makes the Labelfire stand out with all these possibilities is its extremely high print quality«, says Ferdinand Hager, managing partner of Insignis GmbH, highlighting the consistency of the hybrid digital printing system, adding: »Its material diversity and wide range of applications allows us to reduce the complexity of our production steps, which contributes significantly to production optimisation«. Insignis can process an astonishingly wide range of materials on the Labelfire, from 30 µm mono films to 250 g/m2 board and tube laminates, as well as various matt and gloss papers with paper and PET substrates. They also print rough materials, while the variety of materials for inkjet printing is somewhat smaller.

»What makes the Labelfire stand out with all these possibilities is its extremely high print quality«, says Ferdinand Hager, managing partner of Insignis GmbH, highlighting the consistency of the hybrid digital printing system, adding: »Its material diversity and wide range of applications allows us to reduce the complexity of our production steps, which contributes significantly to production optimisation«. Insignis can process an astonishingly wide range of materials on the Labelfire, from 30 µm mono films to 250 g/m2 board and tube laminates, as well as various matt and gloss papers with paper and PET substrates. They also print rough materials, while the variety of materials for inkjet printing is somewhat smaller.

Expansion of the product portfolio

»The question of what has changed at Insignis with the Labelfire is closely linked to the economics of the run length, which is up to 4000 running metres«, explains Ferdinand Hager and adds: »That is the break-even point for one variety of a product. With several varieties, the advantages of digital printing come into play, so the Labelfire is used up to medium run lengths«.

»What makes the Labelfire stand out with all these possibilities is its extremely high print quality«, says Ferdinand Hager, Managing Partner, highlighting the consistency of the hybrid digital printing system.

By producing digitally in short to medium runs, Insignis has been able to optimise production significantly. Labels and packaging are thus produced extremely economically, and their product portfolio has been expanded particularly in the food sector for pasteurisable products thanks to the advantages of digital production. This market with its increasing need for variability of products needs timely and cost-efficient solutions. »The reproducibility of the printed result, with little waste, is not only about time and cost, but it’s also an environmental factor«, Anna-Carin Speneder adds to the statement on the economic efficiency and resource-saving use of materials of the digital inline process.

Insignis recently completed a project with tube laminates for a customer which had invested in a new converting machine. The excellent adhesion of the UV inkjet inks to the laminate was an advantage in this project that contributed significantly to the decision to go digital.

Advantages in existing markets

The high demand for print quality and colour consistency in the cosmetics sector are essential criteria. »This means that you print one job and two weeks later you print it again and you must get exactly the same result«, says Anna-Carin Speneder, describing the Labelfire’s consistency in colour reproduction.

»The reproducibility of the printed result, with little waste, is not only about time and cost, but it’s also an environmental factor«, Anna-Carin Speneder adds to the statement on the economic efficiency and resource-saving use of materials of the digital inline process.

In existing markets, too, the Labelfire with its printing and finishing options offers the prerequisites for implementing customers’ design demands. In the cosmetics sector, for example, Insignis has created a wrap-around label with reverse-side printing, on the adhesive, to accommodate all legal requirements on the label.

Combination of digital printing and digital finishing

The combination of digital printing and inline finishing in one operation is seen as a clear production advantage at Insignis. »We not only benefit economically from this, but also optimise our already high flexibility for the customer«, says Ferdinand Hager. As a result, a great many products can now be printed digitally for which a screen printing form or screen printing unit was previously required. The screen production step is completely eliminated with the DEU. In addition, the DEU achieves 100% register accuracy. For economic efficiency analysis, it should be noted that data for the coating application of the DEU are not always the same for the different types. They change with the variants, and the DEU allows them to be changed almost without delay. This has proven to be an immense advantage over conventional production.

Parameters influencing economic efficiency

»The influencing factors that determine the economic efficiency of digital production play out in a triangle, consisting of the trio of application, run length in linear metres and variety of types«, says Ferdinand Hager, describing the interdependencies of the parameters. »First of all, the print design and material must fit into this triangle. In addition, the run length in linear metres must also fit. If there are several varieties, all varieties must fit in. The varieties allowed us to enlarge the triangle in the direction of the run length. If you stay within this triangle, the Labelfire plus DEU is uniquely advantageous in terms of cost of print because all production steps are done inline.«

Insignis has explored the many possibilities of the Labelfire and gained a great deal of know-how in the process. The customer service team draws on this when it comes to implementing customers‘ visions efficiently, with high quality and cost effectively. A broad wealth of experience in implementing options always opens up new ideas to realise the very demanding designs in cooperation with their customers. »Together with our customers, we realise visions«, is how Ferdinand Hager describes the print-technical possibilities to perfectly deliver products in digital inline production. This is reflected in the many impressive labels, banners and flexible packaging as well as in several awards that Insignis has already won.

Insignis Etiketten Erzeugung und Vertrieb GmbH

The Vienna-based company produces high-quality label and packaging solutions with around 50 employees. Individual and often unusual label and packaging solutions are produced with their modern machinery, which stand out at the POS and help products to attract more attention and success.

Continuously improving processes and products is part of the company’s philosophy, which includes the sustainability of processes. For example, a 2700 m2 photovoltaic system was commissioned on the roof of the company building in October 2020.

〉 www.insignis.at

〉 www.gallus-group.com