Dieter Finna · www.pack-consult.org · (For a German version click here).

Digital label printing has entered the mainstream. According to market researchers such as Smithers, one-third of the market’s value is already produced digitally or in hybrid form. At the same time, the barriers to entry for printers are decreasing — evident in the Gallus Alpha entry-level model, which the Swiss press manufacturer presented in a “prototype design” at Labelexpo Europe.

Gallus’s new development attracted attention at the industry event not only for its technology but also for its striking product design. In contrast to the strictly shielded prototype models seen in the automotive industry, visitors to Barcelona were able to experience the configuration and technology of the digital press firsthand. The system is particularly appealing to label printers looking to expand their equipment with a compact roll-to-roll digital press — as well as to companies planning their first step into digital printing. The Gallus Alpha makes this entry low-risk and economical, without the need to immediately invest in a large high-performance system whose initial utilization is often difficult to predict.

High performance, minimal space requirements

The Gallus Alpha is designed for production environments with limited space. Thanks to its compact, robust monoblock design, the machine is easy to install and quickly ready for use. To start production, it only needs to be filled with ink and the substrate qualification carried out. Looking at the machine’s design reveals that the engineers have focused on core functions and the performance of the digital printing system.

Beginner-friendly system architecture

The system architecture minimizes operator training time. The roll-to-roll design enables easy operation and seamless integration into existing production environments. This makes the digital press an efficient solution for both beginners and experienced digital printing users in the label market.

Printing Technology of the Highest Level

Cutting-edge printing technology is utilized in the compact design of the Gallus Alpha: It uses Epson D3000-U1R printheads, making Gallus one of the first manufacturers to adopt this technology. With a native resolution of 1200 × 1200 dpi, they precisely place the ink droplets and ensure a consistently reproducible print image. The result is uniform area coverage and exact edge definition across the entire print area. Its addressable resolution of 2400 × 2400 dpi is achieved by controlling the droplet generation based on the jetting frequency, droplet size, and print speed. Operating at a printing speed of 65 m/min, the press combines high productivity with excellent print quality. The printheads eject a droplet size of 3.5 pl, resulting in dot diameters of approximately 60 µm on the substrate. This allows for the printing of razor-sharp microtext, up to pinpoint-accurate, high-resolution graphics—ideal for the demanding label market.

Effortless Operation, Fast Changeovers

The Gallus Alpha is engineered for a web width of 345 mm (13.58″) and a maximum print width of 340 mm (13.39″). It is available in either a four-colour or six-colour configuration, both with optional white. At full speed, the system delivers over 85% opacity for white (L*a*b*-measurement). It uses UV inkjet inks from Heidelberg’s Saphira UA01 series, which are cured using modern, air-cooled LED UV lamps.

A non-contact cleaning unit keeps the printheads and nozzle plates clean without touching delicate components, simplifying operation, reducing maintenance time, and minimising the risk of damage. The outcome is higher process reliability, consistently excellent print quality, and an extended printhead lifespan.

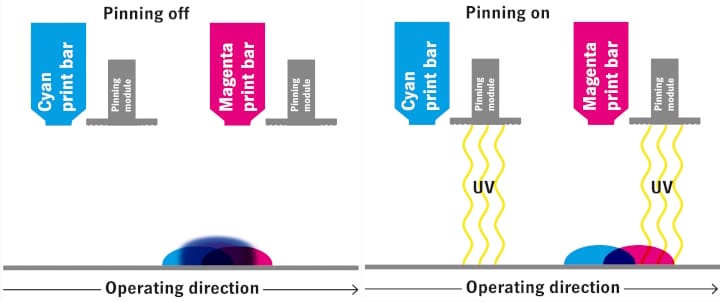

Pinning for Perfect Prints

The Gallus Alpha enables precise control of droplet size for each individual colour — cyan, magenta, yellow, black, or special colours — through advanced single-colour pinning. Depending on the substrate, the variable output of the air-cooled LED UV lamps instantly fixes each droplet upon contact with the surface, before the next colour is applied. This ensures immediate adhesion of the drops, perfect droplet shape and reliable prevention of colour mixing or bleeding. Complete curing via LED UV radiation and cross-linking occurs only after all colours have been applied, resulting in consistently sharp, reproducible print results. The outcome is print quality at the level of modern high-performance presses, every time.

Learn, Apply, Print with Confidence

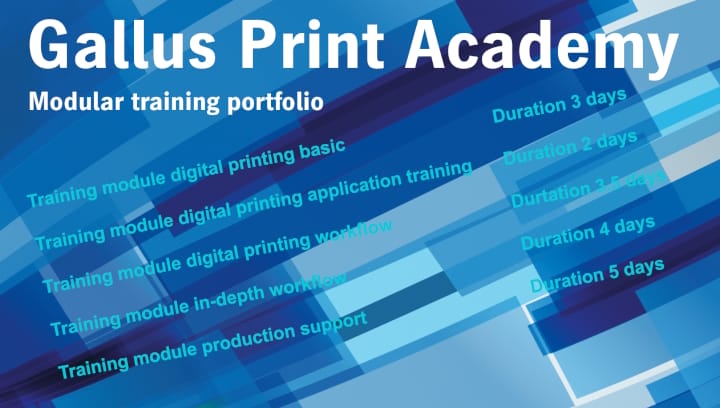

For a smooth start in label printing, the Gallus Print Academy offers a modular training program covering all areas of application. Beginners receive targeted support when transitioning from conventional printing to hybrid or inkjet technologies, while experienced users can deepen their expertise on existing Gallus systems. All training takes place on-site, directly on the production equipment, for a truly hands-on experience.

In the field of digital printing, the training modules are designed to convey the specific ways of thinking and working required by this technology. Key topics include digital workflows, colour management, RIP technologies and the development and implementation of applications. The training is consistently tailored to practical needs, the participants’ level of knowledge, and their individual requirements. Hands-on work on the machine is at the core, enabling users to confidently master the underlying functions and processes.

The modular approach of the Gallus Print Academy promotes lasting learning success. After foundational and application-specific training, participants immediately apply their knowledge under production conditions to consolidate their skills.

Additionally, Gallus offers customised production support. Its duration is determined according to need, typically recommended for around five days, covering workflow optimisation, troubleshooting, in-depth training for specialised jobs like variable data printing, and using HMI parameters to boost efficiency and process reliability. This practical, hands-on expertise empowers users – especially beginners – to quickly unlock the full potential of digital label printing.

Optional Equipment Variants for Effortless Operation

The Gallus Alpha offers a range of optional features designed to simplify operation for both beginners and experienced operators. A standout is the Vision System, which automatically visualises the print image on the Human Machine Interface (HMI). It provides a continuously updated live camera view of the running print, enabling the operator to immediately detect register deviations. In register mode, it is instantly clear whether all colours are perfectly aligned. This web-video functionality ensures precise monitoring and control of the printing process, especially at higher speeds where manual inspection is no longer practical.

The Web Video System can be integrated into the Vision System or used as a standalone solution. Additionally, the Vision System offers advanced functions such as missing nozzle detection and monitoring for density unevenness in solid areas. Algorithm-driven corrections prevent white lines and unwanted rainbow effects that can cause colour drift in solids. The system automatically checks nozzle performance multiple times per day; alternatively, this check can be performed manually by the operator, which requires additional time.

Variable Data

Industrial Variable Data Printing (IVDP) refers to printing QR codes, EAN codes, or variable text within a specific area of a label, covering approximately 10–15% of the total label area. This functionality is included in the standard configuration of the Gallus Alpha, while full Variable Data Printing (VDP) – where each label or larger portions of the print motif are printed fully variably – is offered as an optional feature. Full VDP requires sufficient computing power to generate the image data as quickly as the printing process demands.

For Beginners and Experienced Users

With its low maintenance requirements and intuitive operation, the Gallus Alpha is ideal for a straightforward entry into digital label printing. At the same time, it offers experienced users with existing digital printing systems a powerful retrofit option that integrates seamlessly into existing converting processes such as embellishment or die-cutting.

The digital printing system is fully supported by Heidelberg’s global service network and the World Logistics Centres (WLC), ensuring fast and reliable delivery of original Gallus spare parts and consumables. In case of downtime, trained service personnel provide prompt assistance, including remote login support if needed.

Starting January 2026, the new digital printing system can be experienced live at the Gallus Experience Centre in St. Gallen, SG/CH.

〉 www.gallus-group.com

〉 www.heidelberg.com